SFP Range

Smart Fluid Pac – Accessories overview

Liner types: The innovative concept of bag-in-box liners

A liner, also called in-liner or liner-bag, is a flexible inner receptacle in an IBC container that consists of plastic films and fitments.

Mainly there are two different liner versions: Pillow liners and FormFit™ liners to fit any IBC’s on the market. Any filling and dispense requirements are met by the liners, that are made to carry liquid, high viscous and dry applications. With the two basic configurations, the liner bag design is flexible to adapt to various applications and product requirements. This is done by diversity of the numbers of film layers, film specifications, fitments and other additions.

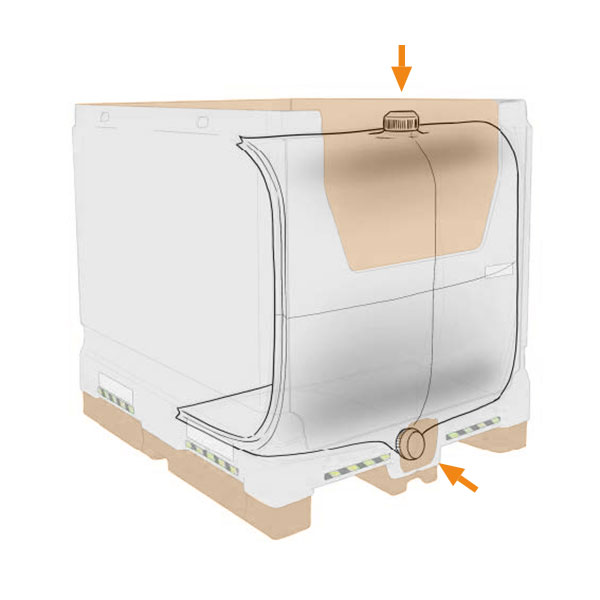

FormFit™ Liner

Benefits:

- Our unique Form-Fit™ design eliminates the need to handle the liners during filling as compared to pillow liners

- The 2” top fitment easily connects with the filling hose

- Easy installment with the option to fill from the top using a bridge, automatic filler or fill from the bottom for IBC’s with no access doors

- Designed for maximum product evacuation with no pockets or folds to trap residual product while emptying

- Available for all IBC sizes (Smart Fluid Pacs, SFP)

FormFit™ Snout Liner

Benefits:

- Our snouted liners enjoys the same great benefits as our standard Form-Fit™ liner

- Added snout for ease of use with hard to reach filling equipment

- Ideal for aseptic applications when used with an aseptic fitment

- Perfect for use with bag-in-box aseptic fillers

Pillow Liner

Benefits:

- Easy installment with the option to fill from the top fitment, automatic filler, or fill from the bottom

- The 2” top fitment easily connects with a filling hose

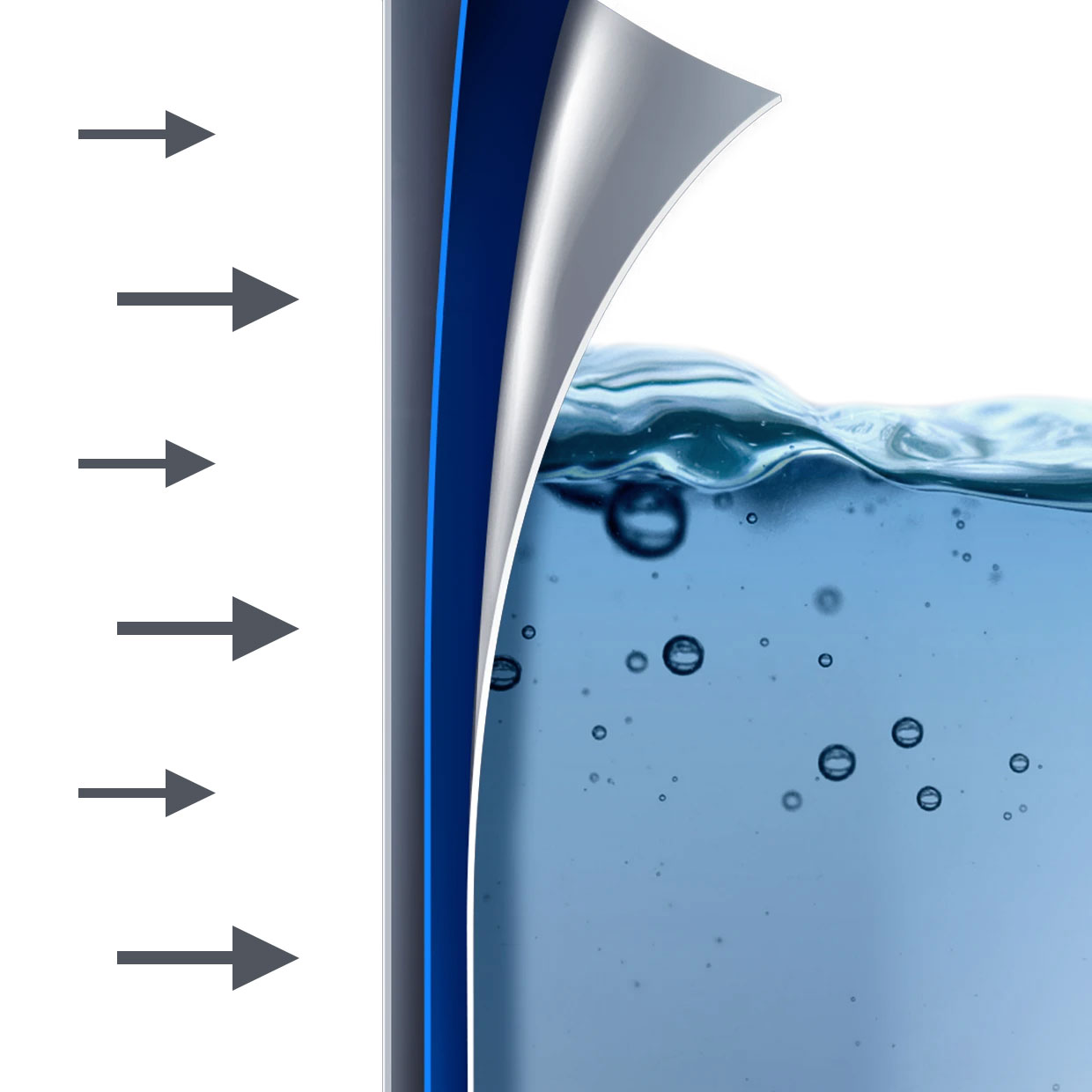

Special Liner films and layers for best performances

Liners are designed to exactly fit any product and environmental requirements and can consist of a divers range of layers and film-types, each providing different characteristics and benefits.

A liner’s aluminum film for example stops oxygen and water vapor from penetrating inside and causing oxidization or fermentation. Such liners are suitable ie. for the fruit and vegetable processing industry, liquid food, beverages, wines, as well as other volatile or oxidizable liquids.

- Flexus mLLDPEe Blue

- Flexus mLLDPE Clear

- Barria Clear EVOH

- Metpet

- Tenalon Coex Nylon

- Hot-fill MLDPE

- Antistatic pink

- FlexusPlus uLLDPE

- Conductive

- Pharmacopoeia

1. Outside influences, 2. Outer layer, 3. Middle layer, 4. Inner layer, 5. Valuable product. (Exemplary multi layer liner with barrier foil.)

Liner Bags are specified by

Film performance

(mechanical properties)

Film performance

(barrier properties)

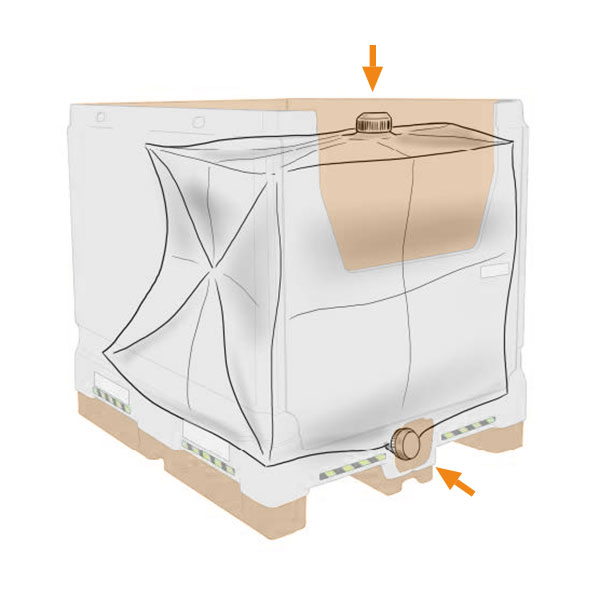

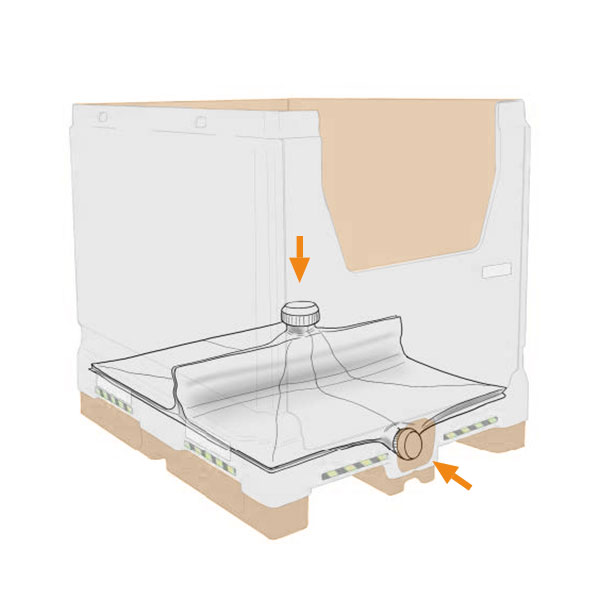

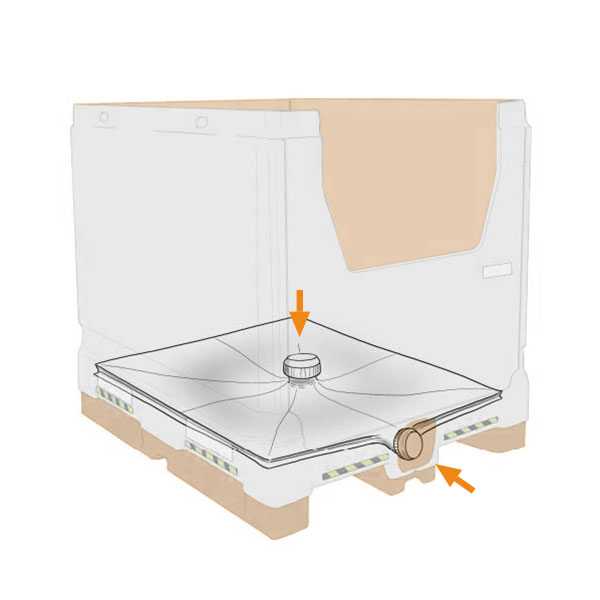

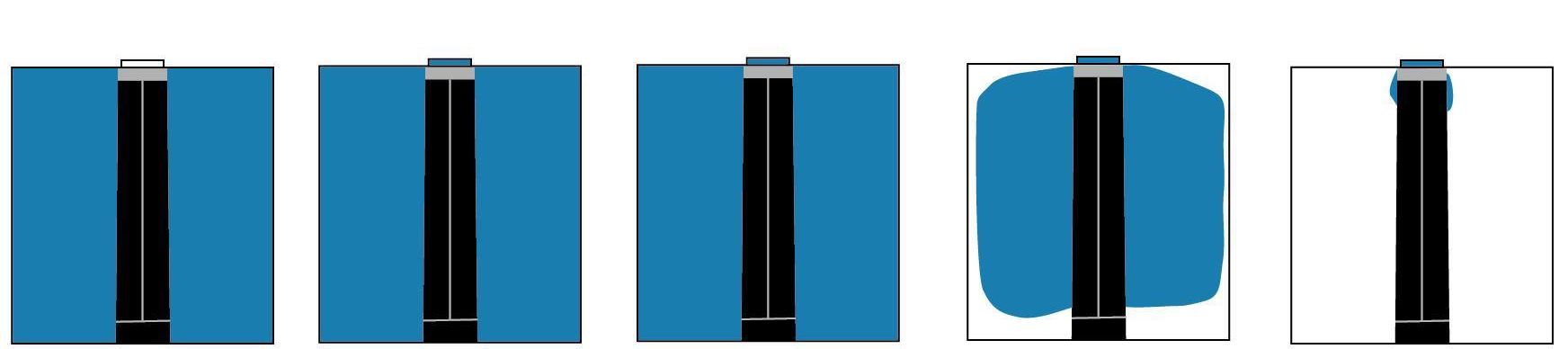

Various filling and discharge methods of the liner types

FormFit™ and Pillow liners have a divers range of filling methods ranging from top, bottom to flat fill.

FormFit™ liner: top fill, bottom fill, flat fill.

- Divers cosmetic products

- Pharmacautical products

- Food high end

- Dairy (aseptic)

- Fruit concentrates (aseptic)

- Fruit preperations (aseptic)

- Flavorings (aseptic)

- Etc.

Pillow liner: top fill, bottom fill, flat fill.

- Liquid-egg

- Sauces

- Dairy

- Bakery sirup

- Edible oils

- Liquid sugar

- Divers cosmetic products

- Etc.

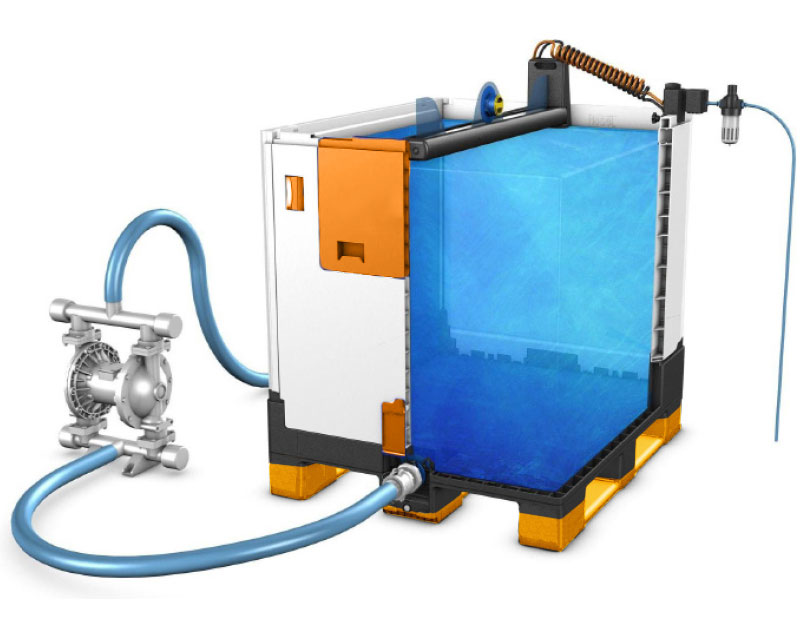

Residue Reduction System (RRS)

Significant residue reduction of high viscose products

The pneumatic version of the RRS is a semi-automatic system that significantly improves the discharge of residual products and materials more effectively, especially for liquids with high viscosity (up to 3,000,000 cp). Without an RRS system, around 8-15 liters of residue remain on average. However, with an RRS system, only around 1.5 liters of residue remain on average, resulting in a up to 90% improvement.

- Residue Reduction System (RRS)

- FormFit™ Liner

- Discharge pump

- Flow valve

- Camlock connector

- Compressed air supply

Resedue Reduction System (RRS) Details

- Lock

- Frame

- Rubber rolls

- Handle

- Air outlet (black)

- Air intake (orange)

- Compressed air switch

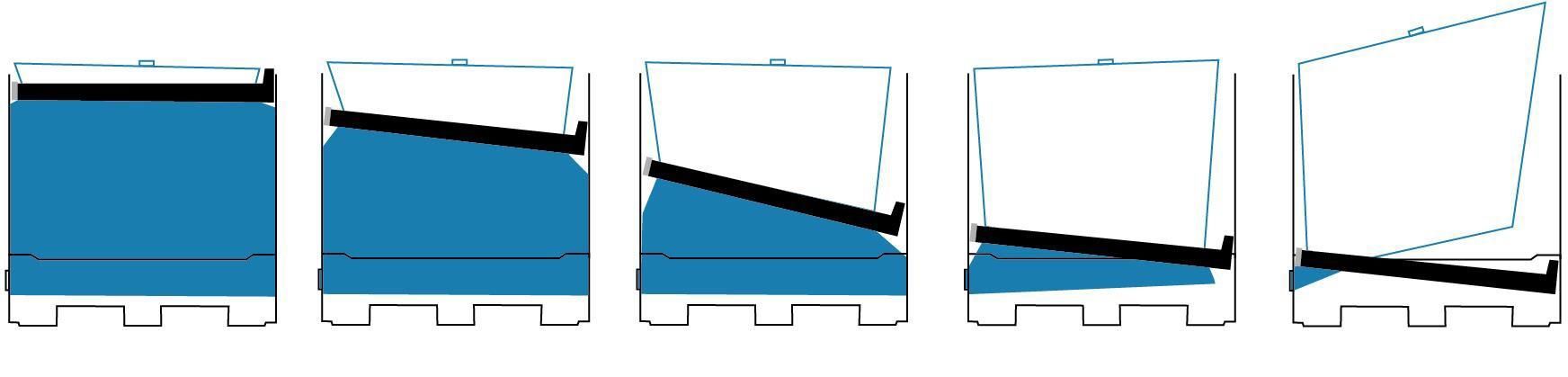

The process of automatically extracting all the liquid (high viscosity)

Process from IBC with FormFit™ liner, filled with high viscous liquid product to empty IBC and FormFit™ liner with very little residue after RRS.

Valves

Non-Steamable & Steamable versions

Butterfly DN50 non-steamable valve

Butterfly S60 (2″) non-steamable valve

Butterfly DN50 steamable valve

Butterfly DN50 steamable valve

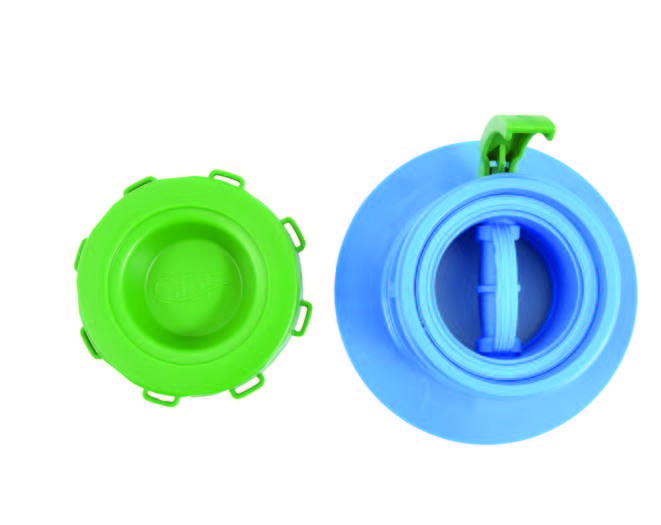

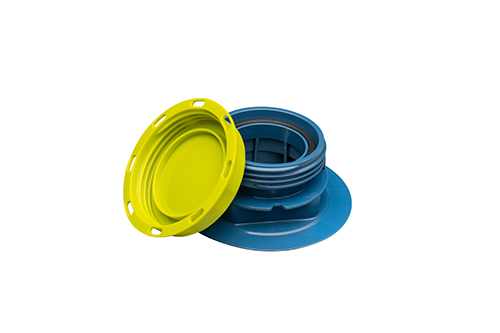

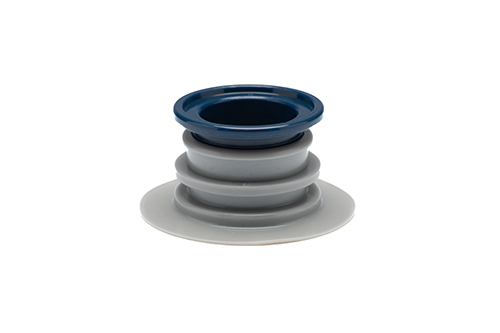

Top Fitments & Glands

1″ & 2″ Aseptic Fitments come in various iterations designed for both hot and cold sterilization and compatible with various types of fillers. Perfect for a wide array of products such as fruit juices, concentrates, preparations, liquid egg, dairy, and more.

The NEW Standard: 2″ Camlock & DN50 Gland enable a straightforward, hassle-free, and hygienic connection without the need for adapters. All components are engineered to eliminate the necessity for couplers. Well-suited for any scenario where a 2-inch BSP (British Standard Pipe) connection is utilized.

Classic 2″ & 3″ BSP Gland: These components are typically employed for general purposes and non-aseptic applications and are available in common 2-inch and 3-inch sizes.

6″ Butress Gland

2″ BSP (British Standard Pipe)

3″ BSP Gland

1″ Aseptic low spout with blue screw cap

NEW Standard: DN50 Gland

NEW Standard: Camlock 2″

1″ Aseptic KM

1″ Aseptic Elpo

Innovative top-fitment solution for all liners

2” BSP risks and inadequacies

- Additional couplers required (plastic or steal)

- Additional investments for couplers

- Risk of contamination from unhygienic couplers that have not been cleaned after the last use

- Risk of inside threads causing plastic particles to enter into the product

- No tamper evidence feature: After filling, the cap can not be connected with the BSP gland with a tamper proof seal

- Missing recycling code 2 HD-PE on cap/gland

The innovative solution: 2”CAMLOCK and DN50 GLAND

- No additional couplers required

- Cost savings by eliminating additional couplers

- Connection is now from the outside instead from the inside of the gland

- Eliminating the risk of contamination through plastic particals

- Tamper evidence feature available: After filling, the cap can be connected with the gland with a tamper proof seal

- Recycling code 2 HD-PE on every cap and Camlock/DN50 gland

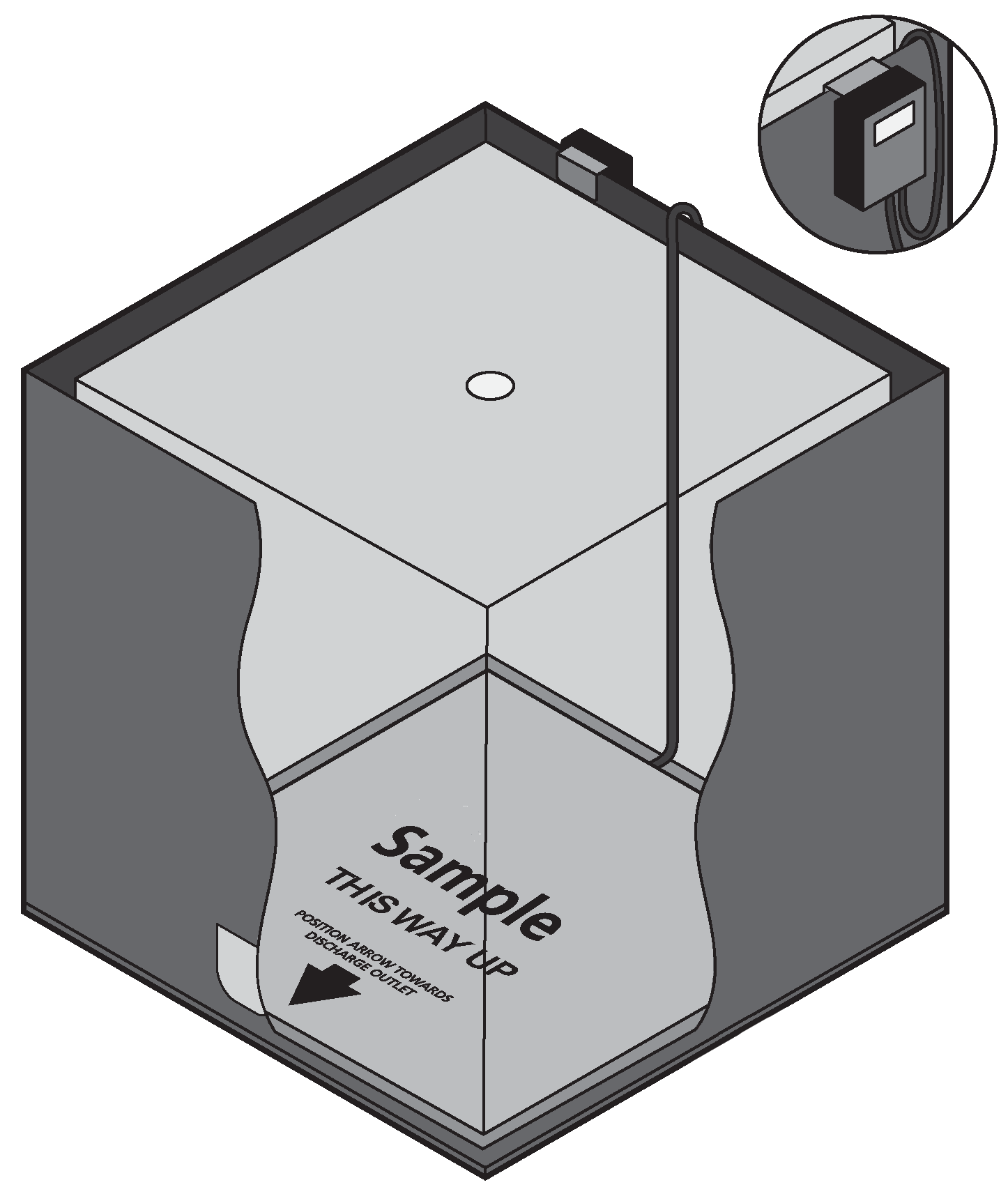

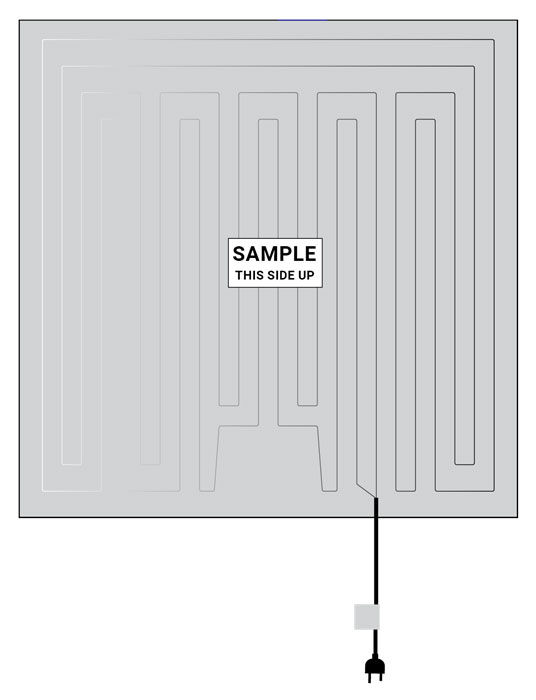

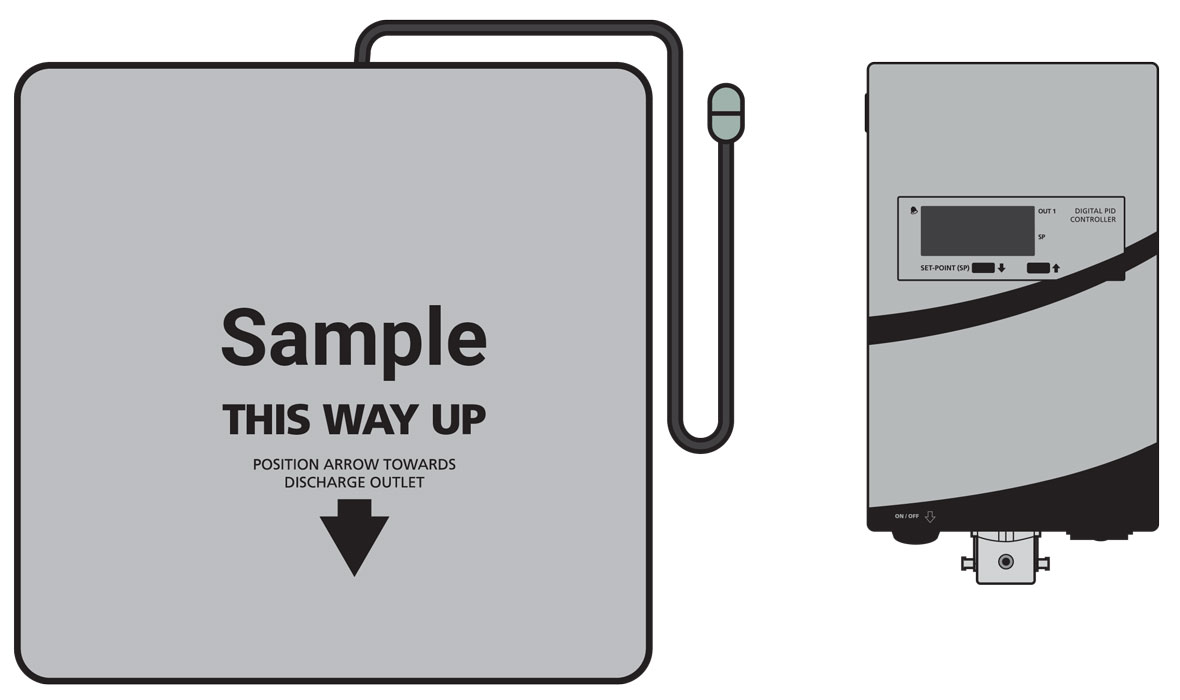

Lightweight, heating systems

Maintaining flow properties through efficient IBC heating

There are two types of lightweight heaters available: the single trip and the multi trip heater. The single trip heater is pre-attached to the liner, offering a easy to use solution for one-time usage. The multi trip heater is placed inside before liner operation and is designed to last for thousands of trips and uses.

Both heaters have a digital controller that allow precise temperature control and are easy to install in- and remove from a IBC. The Intuitive temperature control quickly and efficiently ensures effective heating of hard to heat products.

The heating pad is a sustainable and high-performance solution designed for viscous liquids in an IBC, offering most efficient and controlled heating at a lower power consumption than alternative solutions. It is very easy to install, clean, and service.

- IBC

- FormFit™ liner

- Lightweight heating pad (multi trip)

- Digital controller

Foil heater (single trip use)

Lightweight heating pad (multi trip use)

Heating system reduces residue of following applications

(ex. vegetable, fish)

corn syrup, tapioca syrup, rice syrup etc.